leaching gold plant

The process design of gold leaching and carbon-in-pulp

2009year8month27day Assuming that a gold ore has been effectively ground to ensure maximum economic liberation of gold, the circuits that will have the most effect on the successful operation of a gold plant will be that of the leaching and carbon-in-pulp circuit (CIP).

دردشة على الإنترنت

Review A systematic review of gold extraction: Fundamentals ...

2022year10month15day Gold microbial leaching can be divided into direct microbial leaching and microbial-assisted leaching from the perspective of the mechanism (Yaashikaa et al.,

دردشة على الإنترنت

Gold Cyanide Leaching Process - Metso

Metso's cyanide leaching plants are available as gold adsorption directly from the process slurry in carbon-in-leach (CIL) and carbon-in-pulp (CIP) processes. In addition, dissolved

دردشة على الإنترنت

Finding the Costs: How Much Does a Gold Leaching Plant

2023year7month25day A gold leaching plant is a facility that utilizes various chemical processes to extract gold from ore. The plant typically consists of several components, including

دردشة على الإنترنت

A review of environmentally friendly gold lixiviants:

2023year6month1day Currently, leaching, particularly cyanide leaching, is the dominant extraction process for gold. More than 83 per cent of the world's gold is extracted via cyanidation

دردشة على الإنترنت

Factors influencing the rate of gold cyanide leaching and adsorption

2011year5month1day A better alternative is to use models that adequately describe the rate of leaching of gold from a particular feed and the rate at which that gold loads onto

دردشة على الإنترنت

(PDF) A systematic review of gold extraction:

2022year8month1day In this paper, related studies about alternative lixiviants and methods such as cyanide, thiosulfate, thiourea, thiocyanate, polysulfides, halides, and microbial leaching are summarized. The...

دردشة على الإنترنت

Thiourea Leaching: An Update on a Sustainable Approach for Gold ...

2022year3month18day Thiourea Leaching: An Update on a Sustainable Approach for Gold Recovery from E-waste. Review Article. Open access. Published: 18 March 2022.

دردشة على الإنترنت

Highly Efficient and Selective Extraction of Gold from

20 小时之前 Thiosulfate leaching has been regarded as a promising alternative to cyanidation, but it still faces the challenge of the recovery of low content of gold from high

دردشة على الإنترنت

10TPD Small Scale Mobile Gold Leaching Plant

2020year4month4day The “10TPD Small Scale Mobil Gold Leaching Plant” is a kind of mobility, which can complete all professional non-professional tests in the mining area, and is also a beneficiation plant in production status.

دردشة على الإنترنت

Review A systematic review of gold extraction: Fundamentals ...

2022year10month15day Currently, the thiosulfate gold leaching operation at the Goldstrike mine, Nevada, of Barrick Gold Corp is the only large-scale gold extraction plant with an alternate lixiviant (Azizitorghabeh et al., 2021). Although research on sulfur-containing lixiviants has been the most common in gold hydrometallurgy in the past three decades, few ...

دردشة على الإنترنت

Gold leaching plant (GOLD CIL PLANT) - Pineer

2023year7month6day The Pineer gold cyanide leaching process enables sustainable and cost-effective gold recovery >90%. Comes from one supplier, responsible for the whole package. Provides mechanical and

دردشة على الإنترنت

Typical 10TPD Mobile Gold CIL Plant - Dasen Mining

December 6, 2023 / in Knowledges / by Dasen. A 10TPD Mobile Gold CIL Plant is a compact and portable gold processing plant that can be used to extract gold from ore samples or tailings. It is designed to be easy to transport and set up, making it ideal for small-scale gold mining operations or use in remote locations. Processing Capacity.

دردشة على الإنترنت

A review of environmentally friendly gold lixiviants:

2023year6month1day Lixiviant Gold ore Mineralogical phase Pre-treatment steps Leaching conditions Gold extraction; Thiosulfate: Gold ore (Au 94.63 g/t) from a roaster gold process plant south of Kalgoorlie Western Australia (Alymore, 2001).Sample consisted mainly of pyrite with quartz, muscovite, chlorite, albite, ankerite, paragonite and traces of rutile.

دردشة على الإنترنت

Gold Leaching – Aqueous Pathways - British

Gold Leaching Gold Leaching. Gold occurs in nature as the element (more commonly as an alloy of Au and Ag, or Au and Te, etc.). Ores may contain as little as 1-10 g Au/t (only 1-10 parts per million!). ... The leach solution should not be corrosive to plant equipment and materials. The leach solution should be as non-toxic as possible. Summary ...

دردشة على الإنترنت

Overview of the Challenges and Opportunities in Processing Complex Gold ...

2023year9month30day On the other hand, the addition of ammonia into the Gedabek leaching plant was not found to improve gold recovery (i.e., gold recovery remained constant at 72.5%). Another study by Bas et al . [ 24 ] on leaching copper-rich gold ore (56 ppm Au and 1.1% Cu) using mixtures of ammonia and cyanide indicated both improvements in gold

دردشة على الإنترنت

RioZim commissions BIOX plant, focusing on gold mining

2022year4month25day The plant is expected to increase gold mining efficiency by processing Gold-Sulphur ores. Plant to increase processing capacity by 50 per cent. Zimbabwe Stock Exchange-listed and diversified mining group, RioZim, commissioned a US$17 million Biological Oxidation (BIOX) plant at the Cam and Motor gold mining operation in Kadoma

دردشة على الإنترنت

Lime use in gold processing – A review - ScienceDirect

2021year12month1day The gold processing industry is a large consumer of lime reagents in various forms. Its role in gold processing is mainly as a pH control agent for optimal cyanidation leaching of gold, as well as a neutralization agent in refractory gold processing via acidic oxidation routes. There are, however, a range of conditions upstream of

دردشة على الإنترنت

Review of gold leaching in thiosulfate-based solutions

2021year11month1day In 2003, the plant processed 1.24 million tons of gold ores and produced 55790 ounces of gold in total [30]. In recent years, copper−ammonia−thiosulfate leaching system gets much more attention. ... The gold leaching in alkaline oxygen−thiosulfate solution is demonstrated as 4Au+8S2O32−+O2+2H2O=4Au(S2O3) 23∠...

دردشة على الإنترنت

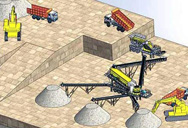

Gold CIP/CIL Processing Plant Solution - Dasen

1 天前 The gold CIP/CIL processing plant is a non-filtering cyanide pulp process that uses activated carbon to directly adsorb and recover gold from cyanide pulp, including seven stages: preparation of leaching pulp,

دردشة على الإنترنت

Characterization of gold-bearing tailings by diagnostic leaching

Characterization of an iron oxy/hydroxide (gossan type) bearing refractory gold and silver ore by diagnostic leaching. Transactions of Nonferrous Metals Society of China, 1286-1297. ... Diagnostic leaching as an analytical tool for evaluating the effect of reagents on the performance of a gold plant. Minerals Engineering, 5(3-5), 503-512. DOI ...

دردشة على الإنترنت

(PDF) A systematic review of gold extraction: Fundamentals ...

2022year8month1day gold leaching operation at the Goldstrike mine, Nevada, of Barri ck Gold Co rp is th e only lar ge- scale gold extraction plant with an alternate lixiviant (Azizitorghabeh et al., 2021). Although

دردشة على الإنترنت

Summary of Gold Plants and Processes - ScienceDirect

2016year1month1day Summary of Gold Plants and Flow Sheets Discussed in Gold Ore Processing, Second Edition. Implemented with tube autoclaves 1.5 km long and 5 cm inner diameter. Leaching at ambient temperature and 5 MPa oxygen pressure and 0.2–0.5% NaCN; 15 min residence time for 85% recovery. Cyanide oxidation negligible.

دردشة على الإنترنت

Exploring Non-ammoniacal Thiosulfate Gold Leaching and

2024year3month13day The application of pressure oxidation (POX) followed by thiosulfate gold leaching is an efficient method used to extract gold from double refractory gold ores containing both sulfide and carbonaceous matter. This process is expected to result in high gold recovery rates, as it liberates gold from sulfides and eliminates the preg-robbing

دردشة على الإنترنت

10TPD Container Type Portable Gold CIL Plant Operations

2023year12month6day The 10TPD Container Type Portable Gold CIL Plant offers a valuable solution for small-scale gold mining operations. By optimizing each stage of the gold recovery process, including crushing and grinding, leaching, carbon adsorption, smelting, and tailings management, global traders can maximize gold recovery, enhance

دردشة على الإنترنت

Metso Outotec Gold Refining Plant

2021year8month3day The Metso Outotec Gold Refining Plant is the result of more than 30 years’ experience in developing robust and cost-efective solutions for precious metals recovery and refining. The process has been successfully applied worldwide in installations with annual gold refining capacities from 1 to 50 tons. The gold refining process is purely ...

دردشة على الإنترنت

Enhancement of Gold Heap Leaching by Using a Reagent

2020year11month11day A relatively low yield during precious metal recovery by heap leaching (50 to 80 %) is associated with a number of reasons, including the difficulty of selecting the optimal process parameters due to the wide range of gold grain sizes: ultra-dispersed (nano-range) — from 10 –9 to 10 –7 m, fine-dispersed (meso-range) — from 10 –6 to 10 –5 m,

دردشة على الإنترنت

شاهد المزيد

- محطم نوع جديد الكرة

- مبدأ العمل لمطحنة الكرة

- شراء مصانع تكرير الكروميت

- مصنعي آلات الطحن الصناعية

- الروتاري محطم خام الذهب المكثف

- cara pengolahan bahan emas

- سوق المعدات الثقيلة المستعملة في الرياض

- المصنعة كسارة الفك في ولايات متحدة

- مطحنة الكرة المستخدمة للفحم في المملكة العربية السعودية

- الشعبي محطة كسارة في دليل خدمات مصر

- معدات معالجة خام الرصاص في غواتيمالا

- تدفق مخروط محطم مصنع للبيع

- كسارة أولية متنقلة 100 طن في الساعة في مصر

- كسارة الصخور في مقاطعة إليس بولاية تكساس

- أحدث التقنيات في طحن